Welcome to another Tesla Tuesday!

We just crossed 40,000 miles on our 2022 Model Y after almost exactly two years of ownership. I’ll use a similar format to the 20,000 mile review.

Cost

While I’ve always been interested in EVs as technology, I was never willing to pay extra to get it. The key reason we jumped into the Tesla was because I believed we could break even on the cost. I have a detailed data pipeline set up to track everything I can about our costs. By tracking the prices of gas stations around my home daily and comparing it to how many miles we drove each day, I can calculate that we would have spent $8,047 on gas using the Ford Escape that we would likely have purchased instead of the Model Y. Instead, we have spent $1,722 on electricity for charging.

- 91% of the charging was done at home for $0.11/kWh

- 7% of the charging was done at super chargers on road trips for around $0.40-0.45/kWH

- 2% of the charging was done at free chargers like Airbnb’s

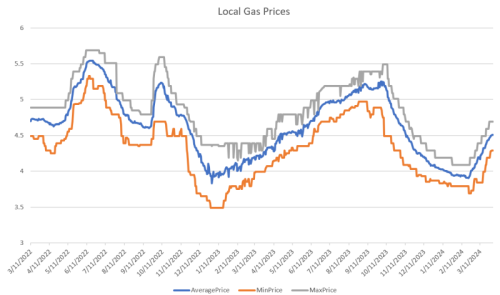

Based on the prices of the Model Y and the Escape when we bought our car, I estimated that we would need to save $18,000 to break even. The bulk of that savings is going to come from not buying gas which means that the more gas costs, the faster we break even. Here’s a chart showing the daily gas prices for the half dozen stations closest to our house (which includes a Costo gas station.)

Based on the data so far, I estimate that we’ll save about $15,000 in gas in the first 100k miles if gas prices stay in the same range.

A big chunk of the rest of the savings should come from reduced operating and service costs. There are no oil changes or brake replacements and there are a lot fewer moving parts to wear out. Up until a few weeks ago, we hadn’t bought anything more than windshield washer fluid for the car. But we did buy tires so that was a major purchase. As a quick update to that tire post, the new tires have been working out well. Efficiency was a major part of my research and while it’s difficult to tell over just the first couple thousand miles, I’m not seeing anything that indicates a measurable decrease in efficiency.

I do think that state registration fees are hurting us more than I expected. Our area keeps voting in more and more taxes so, for example, we spent $939 to register the Tesla in 2023. A large portion of that price is based on how much the state says your car is worth so having the extra value in the car does mean it’s $100-200 more/year than Escape would have been.

A major repair bill with the Tesla could change everything, but at this point we’re on track to “break even” even with pessimistic calculations. For example, my $18,000 goal assumes that we the Tesla and the Ford would have lasted the same number of miles and would have sold for the same amount of money. I’m hoping our Tesla will last longer than the Ford would have and I also expect it to sell for significantly more given the longevity of EVs.

Stats

I’m not going to redo all the stats that I did in the 20k update, but I’ll share a new stat: Battery Health. The TeslaMate software which gives me so much of the data I use to track these costs has a new calculation for battery health. It tries to estimate the actual capacity of your battery against the capacity it had when it shipped. This is not an exact measurement, but it shows that we’re right on track with the expected degradation curve. After 40,000 miles we’ve lost 3.6% of our usable capacity. I did notice during our trip to Utah that there was more degradation, but the numbers have bounced back. I’m not sure if that’s something due to us doing lots of rapid charging or driving in extreme heat at high speeds, but it doesn’t look like anything to worry about. Tesla says that batteries lose about 5% in the first 25,000 miles on their way to losing 12% over the first 200,000 miles.

Experience

The best way to explain our thoughts about this car is that if something happened to it today, I’d pull out my phone and buy another one without much thought. We love this car! Yes, it’s a bit annoying looking like so many other cars on the road, but other than that, it’s a fantastic car to own and drive. We drive this almost exclusively now and I must keep track of the last time I drove the truck so it doesn’t sit too long.

I’ve probably said this before, but I underestimated how wonderful it is to walk out to a “full” car every morning. I always thought that filling up with gas didn’t take that much time so it wasn’t a big deal, but you know what takes even less time? Doing nothing! We pull into the garage, plug in the car and that’s it. It’s full every morning.

I also love the “golf cart” nature of the car. I just hop in and go. There’s no consideration about whether I’ve run the gasoline engine long enough to recharge the 12v battery, burn off the moisture I’m generating in the exhaust system, get all the engine parts fully lubricated, etc.

Consluion

The EV market has changed a lot since we bought our car. The Model Y is now the best selling car of any kind on the planet. It sold 1.23 million units in 2023 beating out things like the Corolla and the Rav4. Not only that, but it was an increase of 66% over the previous year. Tesla factory capacity continues to expand, but estimates for 2024 are all over the place as they are seeing slowdowns like (but smaller than) the rest of the auto industry. 1 in every 12 cars sold in the US is full battery electric. Furthermore, prices on the Model Y have decreased significantly since we purchased and there are federal tax credits at play too. At this point, we love the car so much we’d probably pay a premium to get it, but it’s nice to know that the EV/gas comparison will be more lopsided in the EV’s favor. And it’s even nicer to know, that given our flawless track record with the car so far, we hopefully have a ton of miles left before we start thinking about the next car.

Social Media Pause

About a month ago, I pulled the trigger and removed a bunch of “habit” apps from my phone. Instagram, Reddit, and my news app all got uninstalled. I decided I’d go for at least a week and see what happened. The result scared me enough that I’m still on a break from them.

I found that I would unconsciously pull out my phone and tap the screen where Instagram used to be. I purposely left that spot blank just to make the point to myself and I wish I had a way to track how many times I clicked that empty space!

It’s been a month now. Reddit is still uninstalled and so is my news app of choice. I can still access both of those on the web if I choose to, but that one extra step is enough that I rarely go there. (This isn’t going to be a fun 6 months of US news reading anyway so I’m fine skipping that mess.) Instagram did get reinstalled, but I limit myself to viewing it about once per week and I use the obscure UI menus to only look at posts from people I follow and skip all the suggested posts. Doing that in bulk helps me realize which accounts I’m interested in and which ones were just there to keep my feed populated with new stuff so I’ve been able to cut down on what I subscribe to.

This pause also helped me realize that I do like using Instagram stories to throw random content out into the ether to be consumed by anyone who chooses to use it. It feels more friendly than spamming text threads with too much content (which I probably do anyway.) That’s one of the same reasons that I like keeping this blog up too.

For now, I feel better reining things in a bit so that the phone is mostly just a utility that helps me in my life instead of a dopamine producer that I open out of habit. This isn’t the first time I’ve done stuff like this so I know it will creep back in, but at least there are periods of sanity.